UP12/E-LO 12/24V Electr. Pump For Viscous Liquid, PTFE Gears

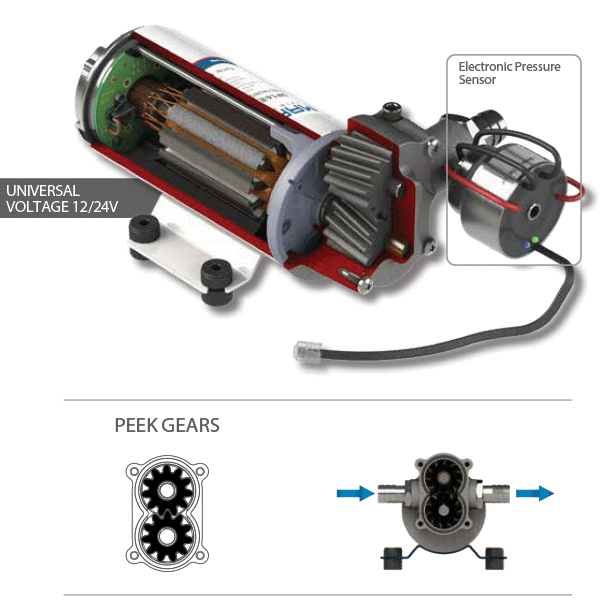

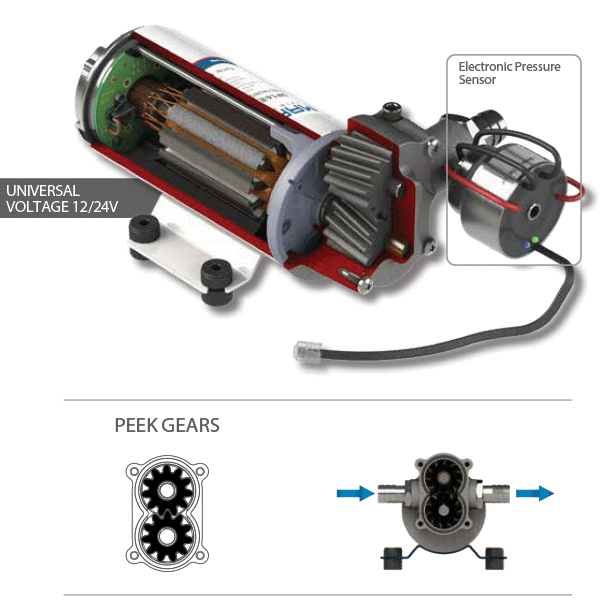

Self-priming automatic electric pump with helical PTFE gears, integrated check valve and electronic control.

Nickel-plated brass body and stainless steel shaft. Main applications: transfer of high viscosity water-based liquids - 3 bar pressure.

This pump features Marco's Intelligent Brain ECU system. The pump is able to detect the constant pressure in the plumbing system and respond accordingly when the pressure drops caused by an outlet being used. The means that the pump can respond to demand and only ever works at the appropriate speed for any given usage. Advantages of this system include:

- Quieter running - pump rarely needs to run at full speed

- Longer lasting - a more mechanically sympathetic arrangement

- Less consumption

- No need for accumulator/expansion tank*

- Intelligent programming and inclusion with digital switching systems

- Fault finding - ECU logs error codes and allows for faster diagnostics

Now featuring the Marco 'Integrated Flange' which seals the motor for extended life of the brushes and lowering of electrical consumption.

* Please consult our technical department if intending to install this pump without an accumular tank. There are some scenarios in which an accumulator tank will still be required.

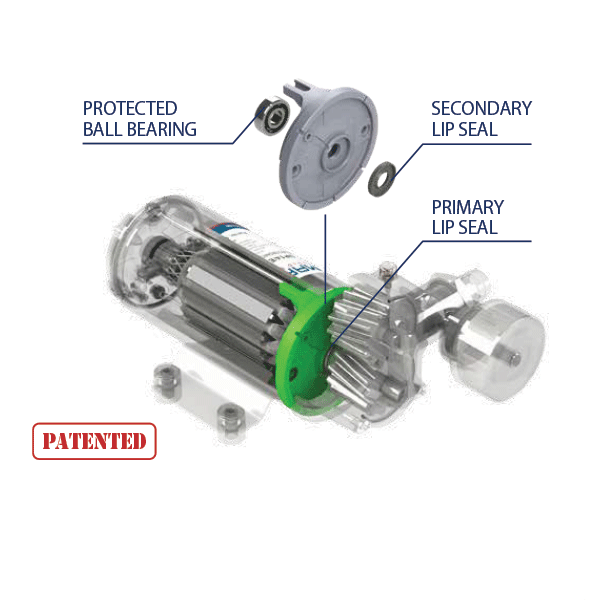

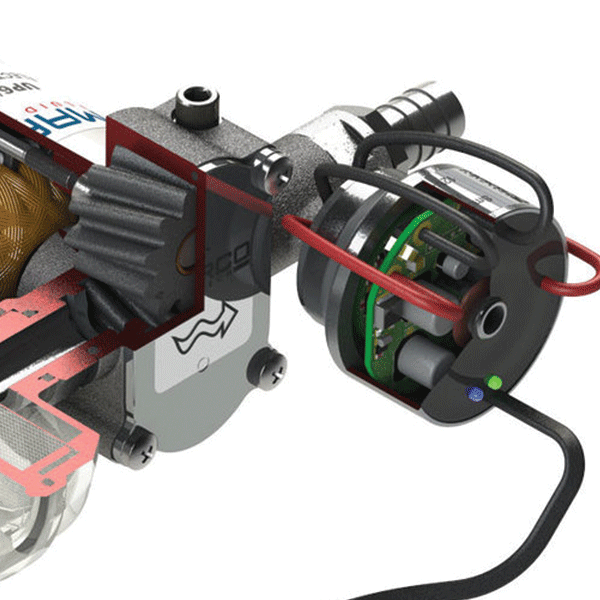

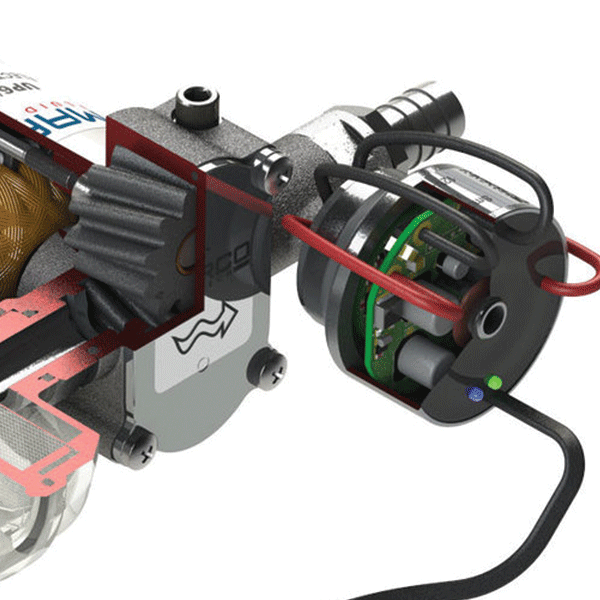

Marco Patented Motor Flange Technology

The innovative flange which isolates the motor housing from the pump gears is an industry first. This clever piece of product design has extended the life expectancy of the Marco pump range, removing the possibility of pump failure caused by condensation build-up in the motor housing. When the pump runs, heat is generated by the spinning motor. Cool water passing through the pump head then adds the conflicting temperature, causing condensation to build. Marco's new flange design allows this condensation to escape the motor housing.

Sealed and dry motor for extended life of the brushes and lower power consumption

Enhanced motor protection

Best performance in extreme hot and cold environments

Highly extended range of fluid temperature tolerance

Thermal and mechanical decoupling for reduced wear and extended seal life

Improved resistance to chemicals

Locked alignment of the pump head

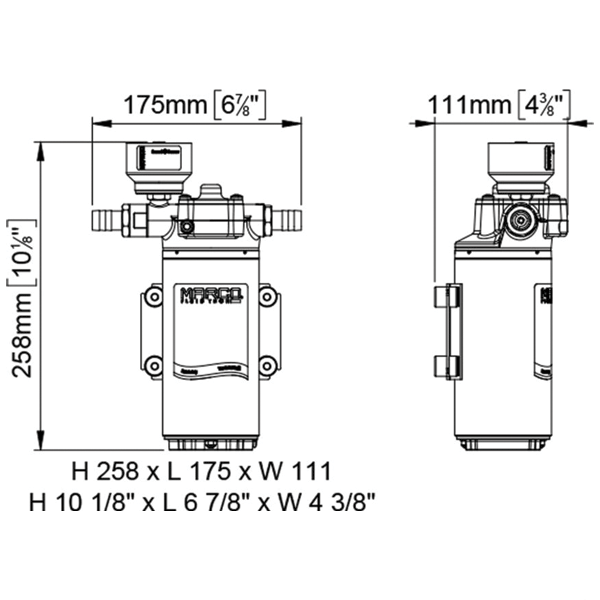

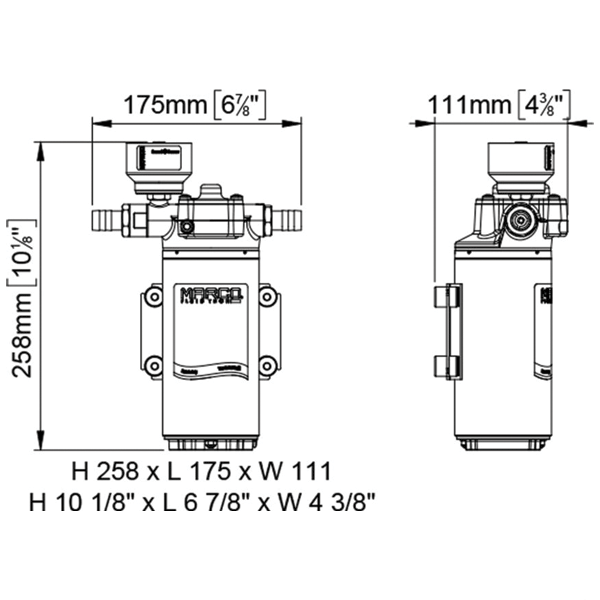

Product Drawing

PEEK Gears

The PEEK gears guarantee constant pressure, heavy duty cycles, lower noise levels and excellent resistance to chemicals. The pump also features a nickel plated brass body and connections, stainless steel shaft, FKM seals and NBR O-rings. The pump is built to last and perform to the highest standard.

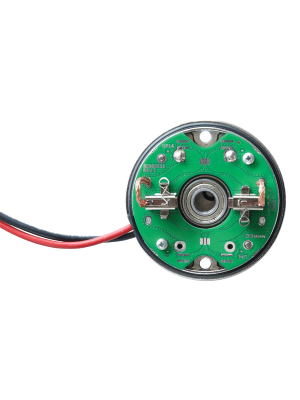

Electronic Pressure Sensor

The PEEK gears guarantee constant pressure, heavy duty cycles, lower noise levels and excellent resistance to chemicals. The pump also features a nickel plated brass body and connections, stainless steel shaft, FKM seals and NBR O-rings. The pump is built to last and perform to the highest standard.

Constant control of pressure, voltage and electrical draw

Protection of the pump from short circuits and overvoltage

Automatic stop when no more liquid is present

Reduction in electrical interferences thanks to the gradual acceleration of the motor

Noise reduction during operation

Optimisation of electrical draw

Reduced wear of components and increased life span of the system

Operative functions signaled by LEDs

*Expansion tank can be ommitted from the circuit as the pump quickly responds to pressure change. TIMAGE reccomends the use of an expansion/accumulator tank in larger plumbing circuits or circuits with washer dryers fitted. Please consult the TIMAGE technical team with any queries: technical@timage.co.uk

PCS Control Panel

The PCS control panel is an optional accessory to the UP3/E pump. Connecting to the pump using the network cable, the panel can be used to remotely monitor the operation of the pump and interact with it.

Remote monitoring of the pump operation and interaction with it: checking of liquid presence and reset in case of malfunction without disconnecting the device.

The “Run” LED indicates that the pump is working and alerts in case of small leaks

in the system, preventing motor damage due to prolonged operation at low speed.

Stop and Start of the pump with a simple push of a button.

Quick connection of the panel to the 3m RJ11/6 terminal cable integrated in the sensor of the pump.

The panel can be recessed in a circular hole of a 70mm diameter or externally

mounted.

The terminal block allows the user to replicate the buttons and leds of the panel

on an external circuit thus favoring a personalized management of the functions

through an external device designed by third parties.

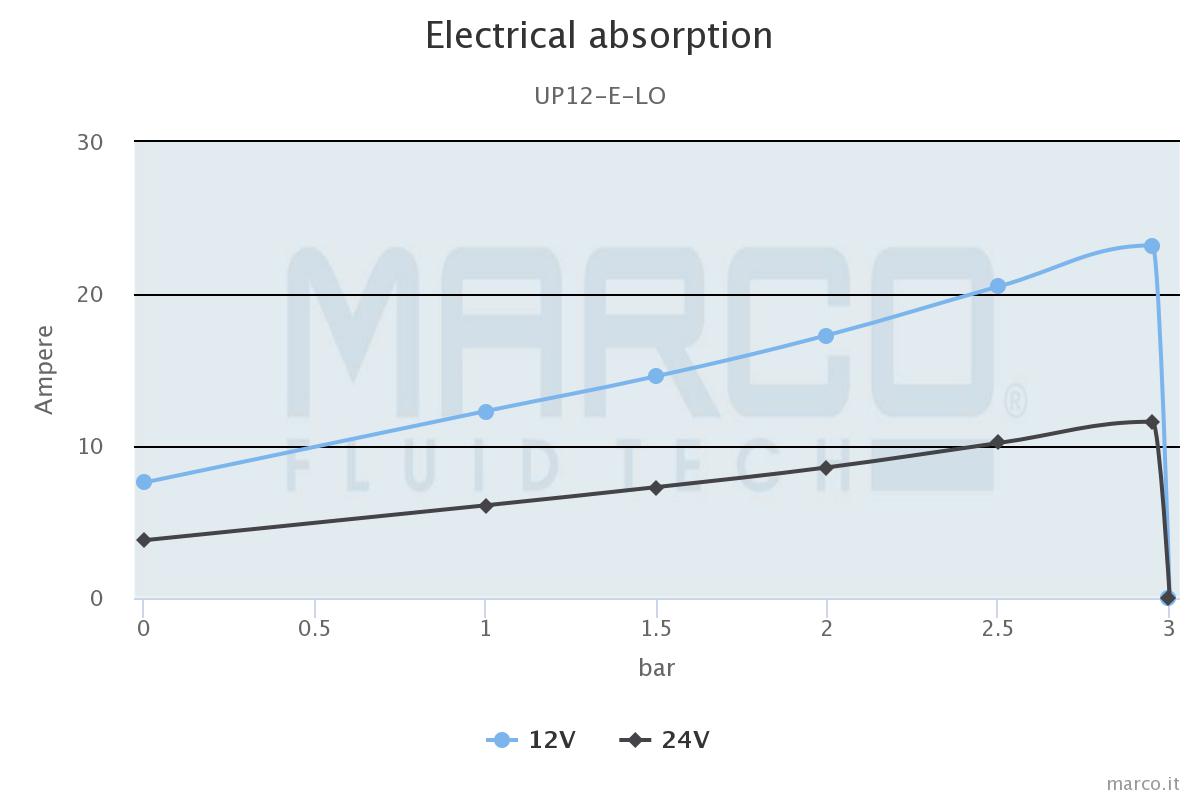

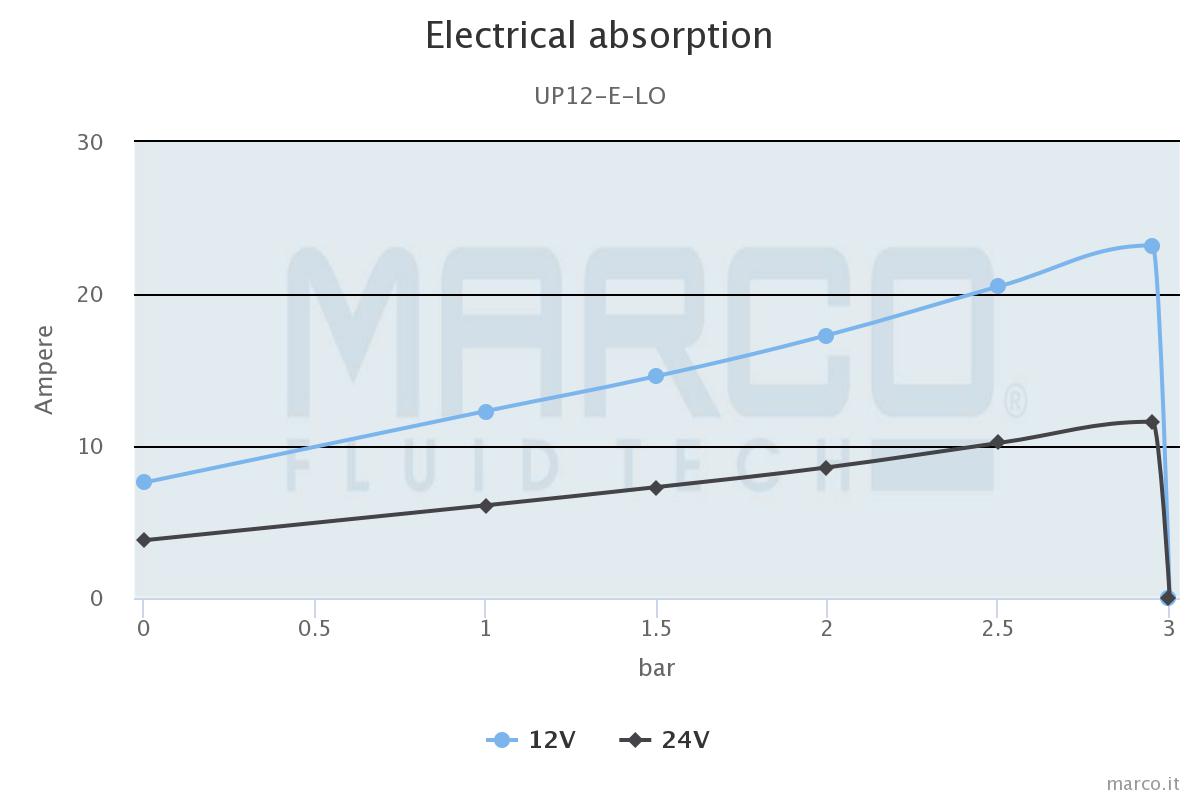

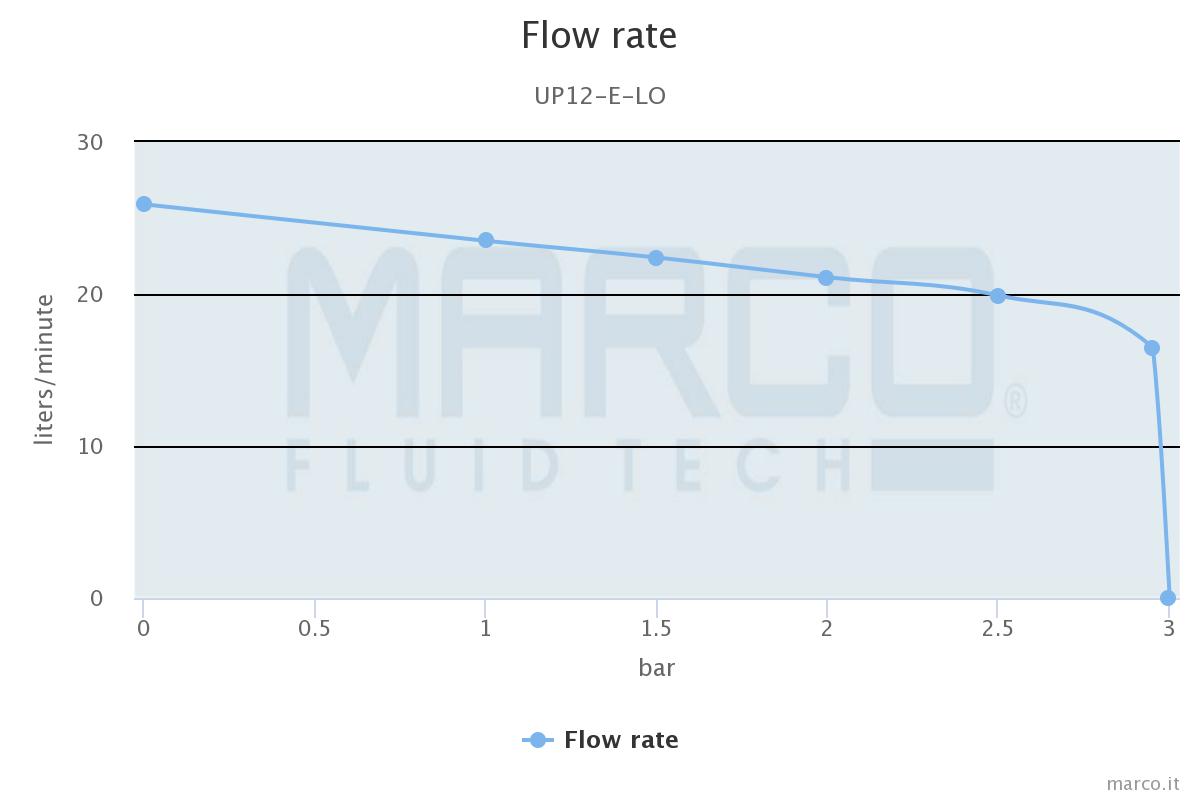

| Input Voltage | 12 / 24Vdc |

|---|---|

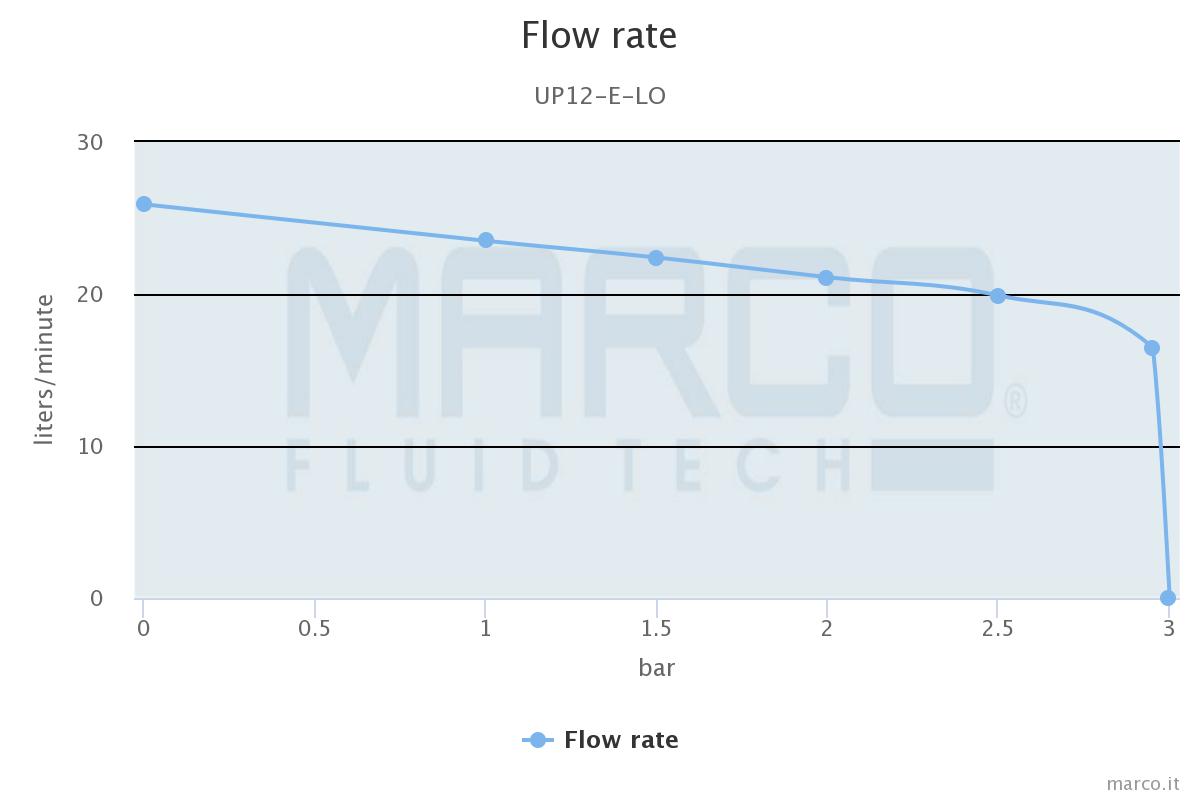

| Flow Rate | 26 l/min |

| Pressure | 3 bar |

| Liquid Type | Water + liquid chemicals |

| Power Consumption | 14 / 7 Amps |

| Motor Power | 360W |

| Fuse | 25 Amps |

| Hose Connection | 16mm |

| Weight (kg) | 4.940000 |

| Manufacturer | Marco |

| EAN Barcode | 8022278609992 |