Marco Pumps - A Market Leading Product Range

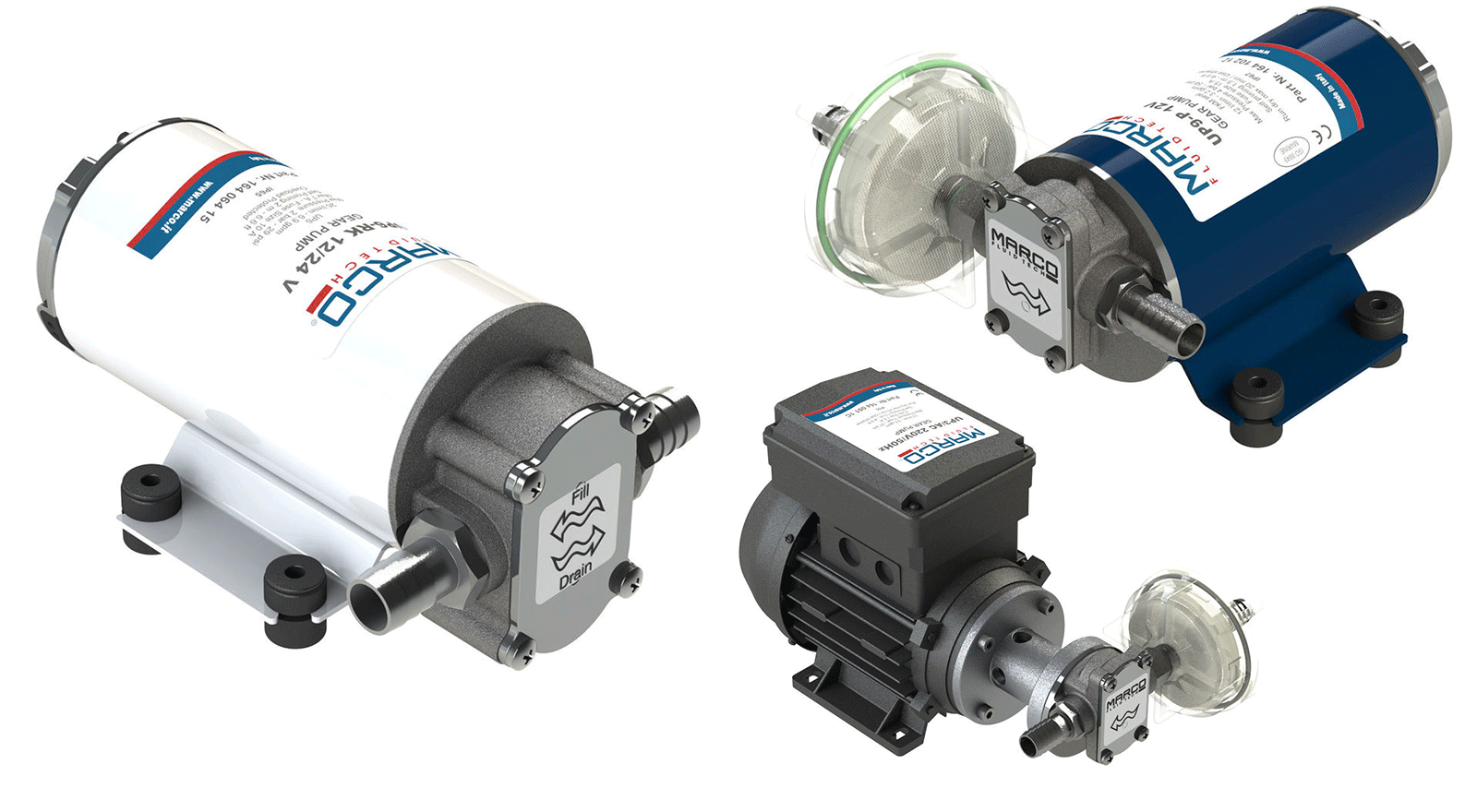

Marco produce an industry leading range of pumps for a variety of applications and liquids. In this article we will be focusing on the advantages and uses of the Marco fresh water pumps but it is worth noting that the same high quality engineering and design can be found in the other pump lines on offer. Marco produces bilge pumps, oil and diesel pumps and pumps for the transfer of antifreeze and other chemicals. Many pump technologies are available from gear pumps to vane pumps as well as pumps for low voltage or high voltage application.

A Marco product has become the pump of choice for many of the world’s leading boat yards as well as some very large automotive manufacturers. The pumps have become renowned for their quality and reliability and the aftersales support offered by Marco together with its distribution network is second to none.

Above - 16468715 Electric Pump

Fresh Water Systems On Board – Intelligent Solutions

Marco pumps pack a vast amount of innovation into their compact housings. No more is this the case than with the range of Electronic Brain pumps. Marco E pumps feature a small ECU sat on top of the pump housing. This piece of tech has moved the game on in the water pump industry, redefining how a water system can be designed.

There are some great and obvious advantages to the E range of pumps but first let me explain how they work.

The E models create a pressurised system on board. The ECU is constantly measuring the pressure in the plumbing system to keep it at a predefined level, normally 2.5 bar. As soon as a tap or shower is used and the valve is opened this causes a drop in the pressure. The pump immediately responds by pumping water in order to maintain the pressure at the specified level. The pump is reactive to a drop in pressure, and here is the clever part. Instead of spinning up to full speed, the pump only pumps at the required speed to maintain the pressure in the system. So, with just one water outlet being used the pump will run slowly. With multiple outlets being used the pump will speed up, reacting to the demand. This brings the first clear set of advantages of a Marco E pump when compared to a conventional unit. A slower pump is a quieter pump, as well as a more efficient pump. The Marco E pumps have a longer life expectancy than a traditional products as the unit spends far less time operating at maximum capacity thanks to it variable speed design. An E pump will also consume less power and create less noise than a conventional fitting, ideal for when sleeping on board.

Another key advantage of a Marco E pump is that often an accumulator tank is not necessary in a plumbing design. More often than not with small systems the expansion vessel can be avoided, removing an extra expense from the overall design as well as avoiding another potential leak point. In craft where space is at a premium, this is a key advantage. We would however always advise a small expansion tank in larger plumbing systems as well as systems with washer/dryer units. With large systems, an expansion tank located far away from the pump can help with maintaining the pressure on board and reduce strain on the pump. Washer/dryer units also require an expansion tank due to their need for a very small amount of water over a long period of time. The expansion tank helps to protect the water pump from excessive heat build-up if operating for long periods. We encourage our clients to consult us during any plumbing system design so that we can best advise on the system requirements.

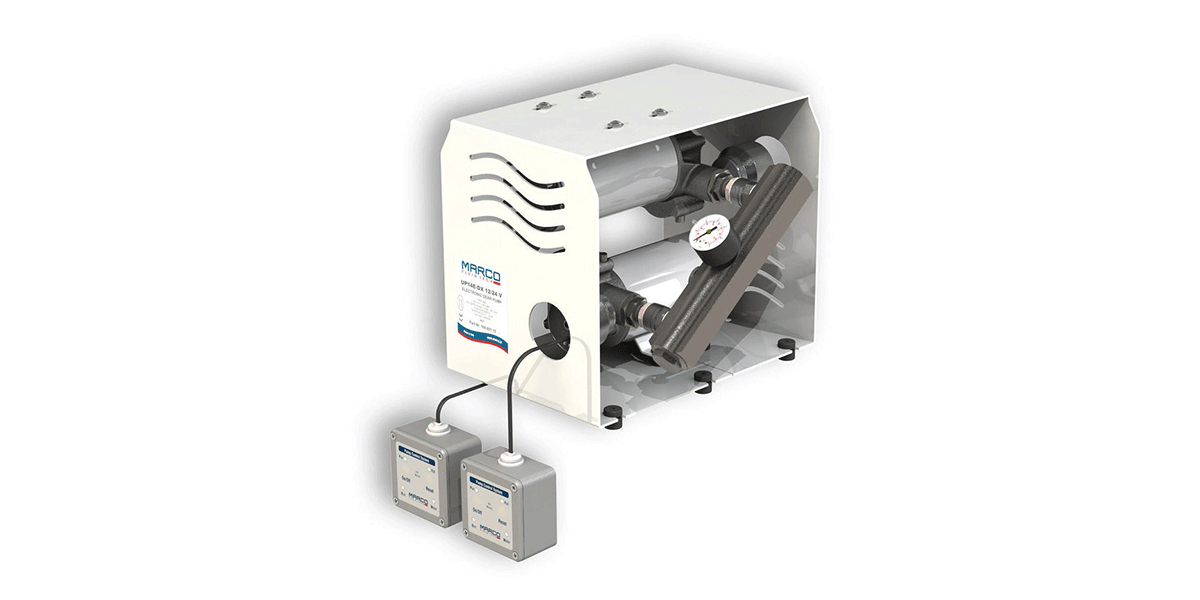

Above - 16468513 Electric Dual Pump System

System Integration

The Marco E pumps offer a level of integration into central electronic control systems as never seen before. A simple control panel is available for the E range which gives users a great deal of control of the pump from a remote location. You can see when the pump is running, diagnose fault codes thanks to the LED communication lights and manually switch on or off the pump. This device provides a handy overview of what the pump is doing, especially useful when pumps are installed in hard to reach areas such as engine rooms or underfloor lockers.

For those looking to go one step further, the E pumps can be controlled from central command systems using digital switching. The same information transmitted to the Marco control panel can be fed into a main system, potentially providing boat owners with pump information from main Multifunction Displays (MFD) on board. This level of understanding of pump activity ultimately can lead to the discovery of problems such as leaks in record time. A system that can communicate that the pump is running when no water outlets are deliberately open can instantly warn you of a leak in the plumbing, potentially avoiding water damage on board.

Continuous Innovation

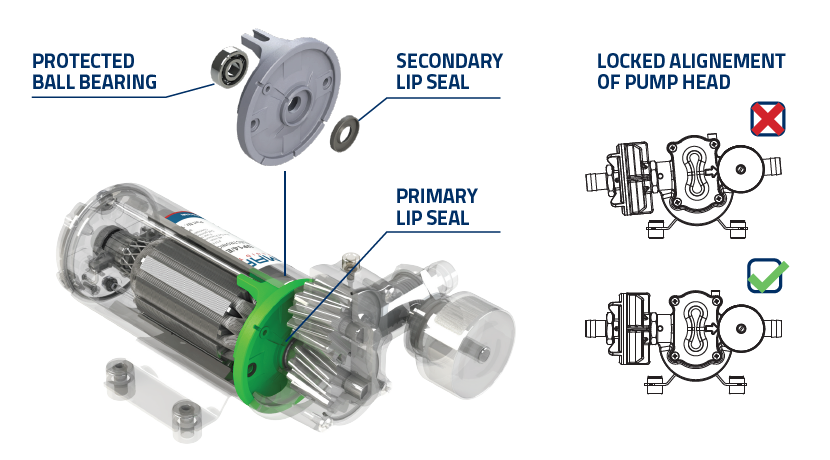

The Marco R&D department never rests on its laurels. They are driven to provide the best possible product in the sector. 2020 will see the introduction of another step forward in pump design and the removal of a common cause of pump failure. A new patented pump housing design will provide protection to the motor against damage through condensation build-up. A common problem that no pump manufacturer has yet overcome, pumps can often fall victim to internal condensation caused by the difference in ambient and water temperature. This new design set to launch in September 2020 provides a solution to this problem, another innovation in Marco’s armoury and demonstration of their commitment to perfecting their pump designs. Look out for this upcoming new development, it’s going to be a game changer.

Update - 12/10/20

We are pleased to announce that the new Marco design has launched.

- Sealed and dry motor for extended life of the brushes and lower electrical consumption

- Enhanced motor protection

- Improved resistance to chelmicals

- Thermal and mechanical decoupling for reduced wear and extended seal life

- 3 TIMES LONGER OPERATIVE LIFE!