Winterising Your Idromar Watermaker: Essential Maintenance for Longevity

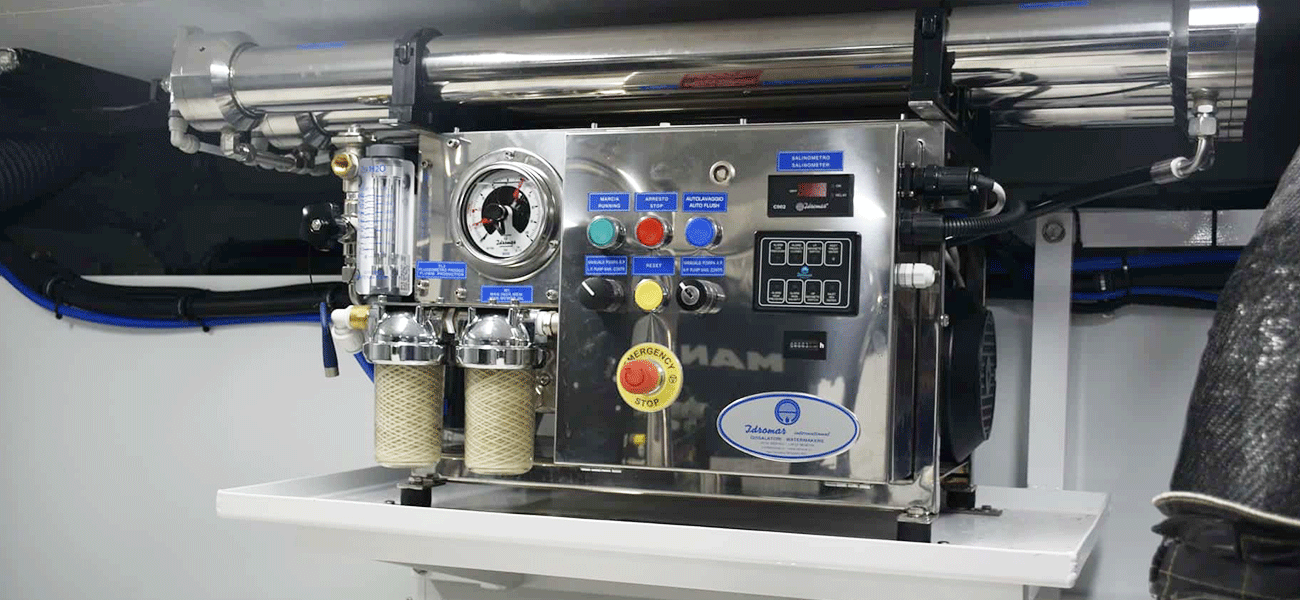

When it comes to yachting, having access to fresh water while at sea is a necessity. Idromar, an Italian company founded in 1982, has established itself as a leader in the marine watermaker industry, producing high-performance, reliable systems tailored for the needs of yachts and superyachts. The brand is synonymous with quality and durability, making it the preferred choice for the finest yacht manufacturers in the UK and across Europe.

A Brief History of Idromar

Idromar started with a vision to create efficient and robust desalination systems capable of withstanding the harsh marine environment. Over the years, the company has continually innovated, developing advanced technology to optimise water production and filtration. By using high-quality materials and rigorous manufacturing standards, Idromar has built a reputation for reliability and longevity. Today, many prestigious yacht builders and owners trust Idromar watermakers to provide fresh, clean water even on the most demanding voyages.

Why Boat Builders Choose Idromar Watermakers

Several factors make Idromar watermakers a top choice among yacht manufacturers in the UK and Europe:

- Engineering Excellence: Idromar systems are engineered for efficiency, utilising the latest technology to maximise water production while minimising energy consumption. This is particularly important on yachts where power resources are limited.

- Ease of Use and Maintenance: Designed with the user in mind, Idromar watermakers are easy to operate and maintain, even for those with minimal technical expertise.

- Durability and Reliability: Built with premium components, Idromar units are designed to withstand the corrosive marine environment, ensuring they perform reliably over time.

- Customisation Options: With a wide range of models and customisation options, Idromar can tailor its systems to fit different yacht configurations, catering to the specific needs of owners and builders.

These qualities make Idromar watermakers the go-to solution for high-end yachts, ensuring that they not only meet but exceed the expectations of yacht owners.

How to Winterise Your Idromar Watermaker

At the end of the season, special maintenance is required to ensure your Idromar watermaker remains in peak condition. This involves a two-step process using two specialised products: MC-K02 for cleaning and MC-K04 for sterilisation. Below is the detailed procedure:

Preparation with MC-K02:

- Dissolve the entire contents of the MC-K02 powder in a clean bucket filled with fresh water. Stir until the powder is completely dissolved.

- It’s important to use a large container to avoid overheating the water during the regeneration process, as a small volume could cause serious damage to the membranes.

- Create a closed circuit with the watermaker system, ensuring the membranes are properly connected for the wash cycle.

- Run the system at approximately 15 bar pressure for 30 minutes to complete the cleaning cycle with the MC-K02 solution.

- Once the process is finished, drain the regeneration tank completely.

Sterilisation with MC-K04:

- Repeat the procedure above, but this time using the liquid MC-K04 product. Pour the entire contents of the MC-K04 into a new 100-litre container filled with fresh water.

- Exercise caution when handling MC-K04: avoid inhaling fumes, and do not touch your eyes if you've come into contact with the product.

- Re-start the system, maintaining the pressure at 15 bar, and allow the MC-K04 solution to circulate for approximately 15 minutes within the closed circuit.

- Once the sterilisation process is complete, empty the regeneration tank.

Final Steps:

- After completing the cleaning and sterilisation processes, reset all valves to their normal operating positions and remove the hoses used for regeneration and winterisation.

- Ensure the 3-way valve is set in a horizontal (closed) position to conclude the winterisation process.

By following these steps, you’ll ensure your Idromar watermaker is thoroughly maintained and protected throughout the winter months.

Why Winterisation is Important for Your Idromar Watermaker

Winterisation is a crucial maintenance step for watermakers, particularly in regions where yachts are often stored for long periods during the winter months. Failing to winterise your Idromar watermaker properly can lead to damage and costly repairs. Here’s why:

- Preventing Freezing Damage: If water is left inside the system during the winter, freezing temperatures can cause the water to expand, potentially cracking filters, membranes, and other components. Proper winterisation ensures all water is flushed out, preventing such damage.

- Protecting Against Corrosion: Even if freezing isn’t a concern, stagnant water inside the watermaker can lead to internal corrosion, particularly when left for months. Winterisation involves using special solutions that protect the system from rust and corrosion during storage.

- Ensuring Optimal Performance: By taking the time to winterise your Idromar watermaker, you not only protect the components but also ensure the system will operate efficiently when the yachting season begins again. This preventative maintenance step can significantly extend the lifespan of your watermaker.

In conclusion, as the colder months approach, it’s essential to prepare your Idromar watermaker for winter. By following the manufacturer’s winterisation process, you protect your investment, ensuring your system continues to provide fresh water for many voyages to come. Replacement parts and winterisation solutions are available to purchase on our online store, and our sales team is ready to assist with any queries you may have.