Product Spotlight - LED Neon Flex

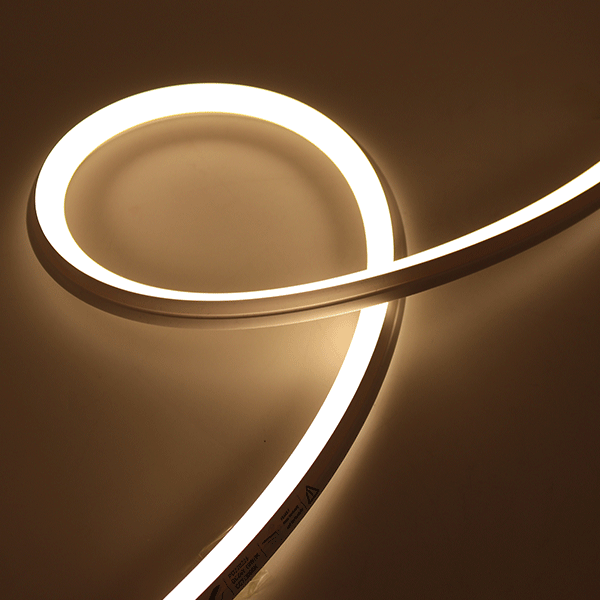

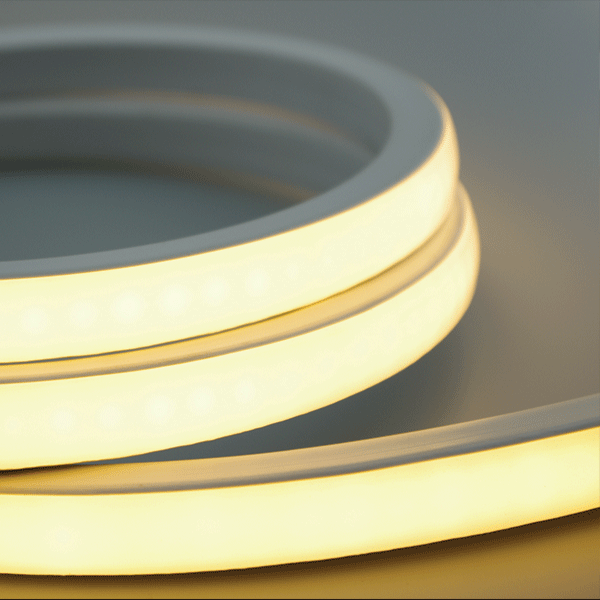

Flexible neon LED lighting is a crucial element to any quality lighting plan. The ambient effects that can be achieved with this superb linear light source can really elevate a space, inside or outside.

Choosing the right flexible neon for your application can seem a complex task, this is why we have pulled together this useful guide to help you with your choice.

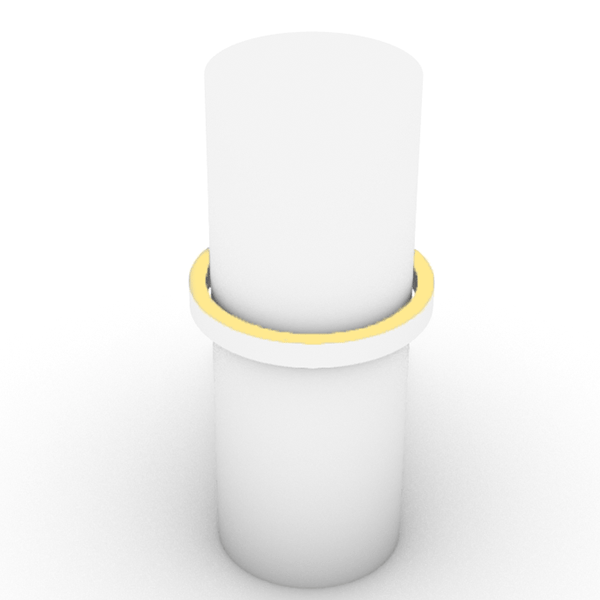

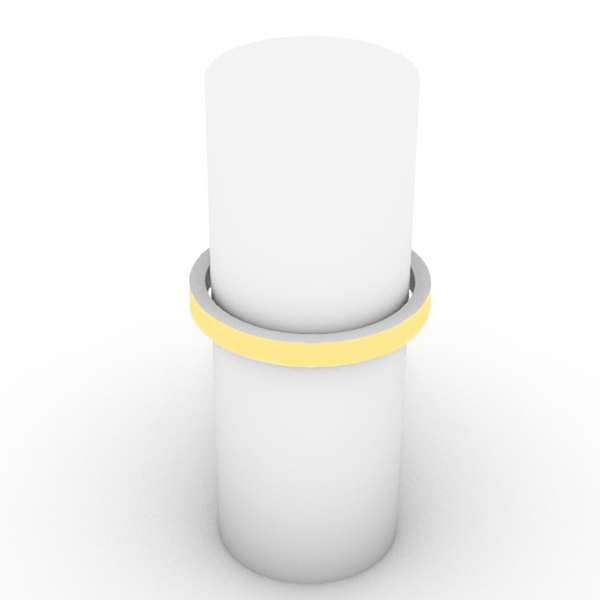

Top View, Side View of 3D Bend?

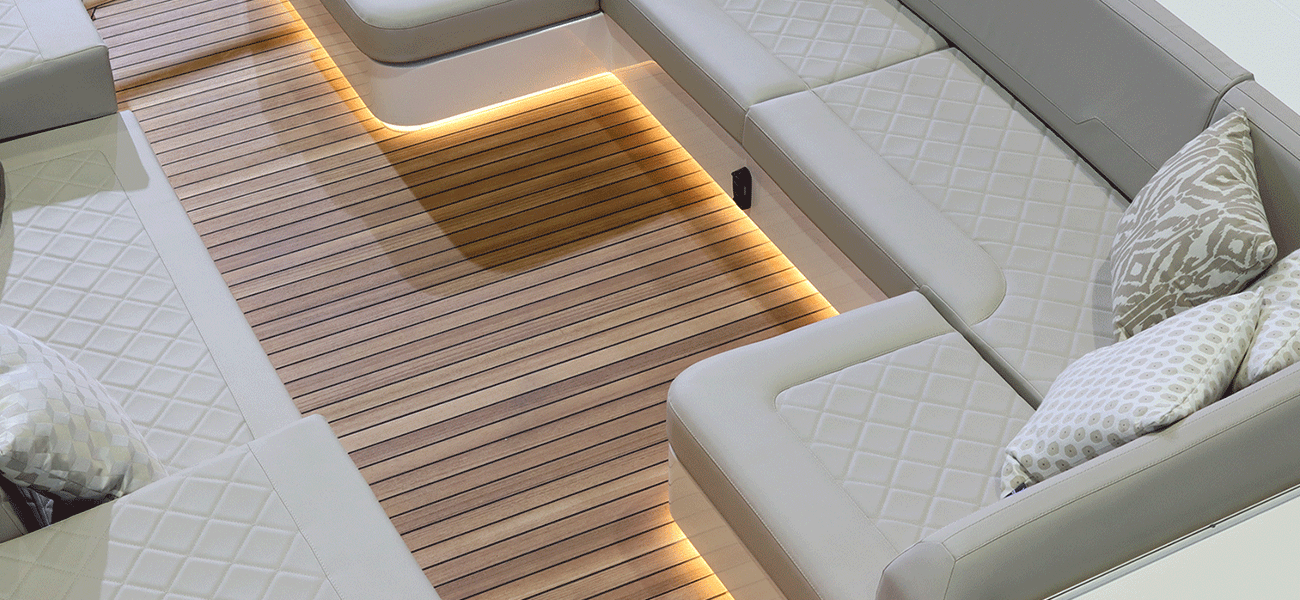

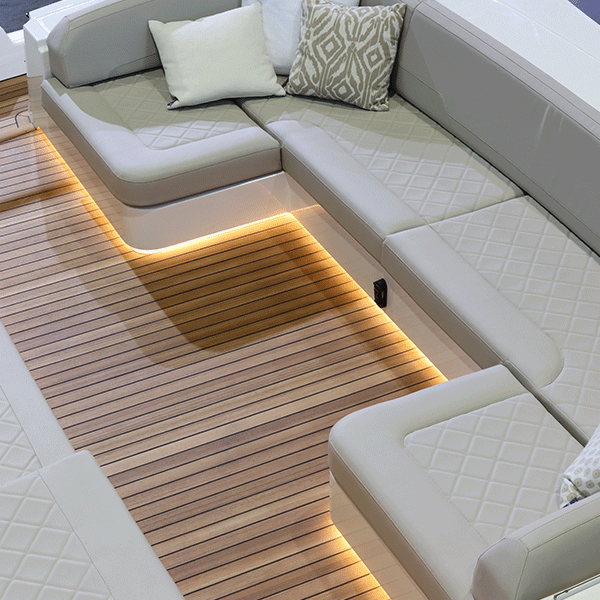

The first thing to establish is how your neon strip needs to flex in relation to the lens direction. Firstly, decide which way the light lens needs to face. Many customers want a flexible neon to provide an indirect ambient light rather than a direct one. In other applications, the neon flex is used as a feature with the lens on show for a dramatic linear light effect. Whichever lighting style you choose, work out where the light output will be projected versus any flex it needs to have. A common application of neon flex is a low level one, below seating or underneath furniture. It is typical to face the lens down at the floor, providing a lovely soft light output which reflects from the floor surface back up into the space. In this case, if downward facing and needing to follow a flowing shape, the product to choose would be side view. If installed in the same location but a horizontal output is required, in order to project light out across the floor surface, then a top view product is the right choice. We often explain to clients our analogy of a lamp post:

If you wrap the neon flex around a lamp post and the light shines either up the pole or down the pole (depending on orientation), then this is side view. It is a perpendicular 90° output in relation to the direction of flex.

If you wrap the neon flex around a lamp post and the light shines directly out at you, then this is top view. It flexes in the same direction as the lens (forwards or backwards).

Side View Neon Flex installed with the lens on show

Side View Neon Flex installed with the light output reflecting off another surface

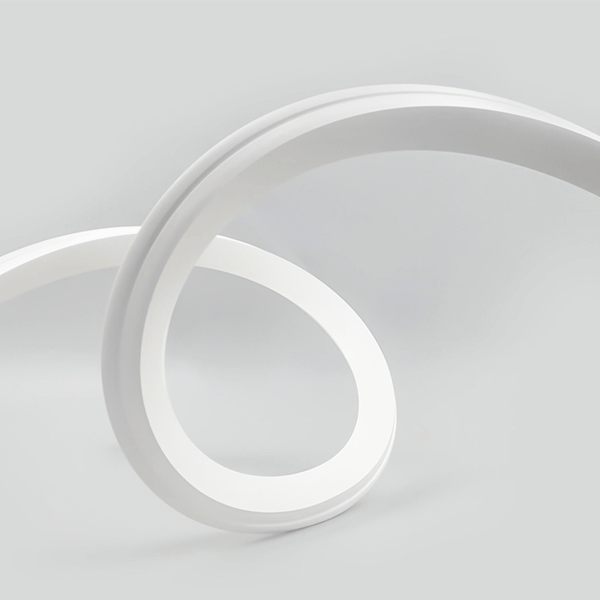

There is now a third way. 3D Bend neon flex is a product which allows flexibility in all directions, that is both side and top. This linear light offers a solution to clients who need to follow multiple axes of curve in a single length of light. At the time of writing, the 3D Bend neon is only available in a single cross-sectional size of 16mm wide x 15mm tall and is a silicone product only (more on that later).

Constant Voltage or Constant Current?

Once you have established whether side, top or 3D Bend is the right physical product, the next thing to consider is the length(s) required. The standard for our linear neon lighting is a constant voltage technology. This is like any normal strip LED and requires a 12 or 24Vdc input to operate. Constant voltage is often however only suitable for lengths of up to 10m powered from a single end. This can be doubled to 20m if powered from both ends but certain applications may not make this possible. For lengths over 10m powered from a single end then a possible solution is a constant current neon. Constant current typology, in the case of our LED neon, does not change how you use or power the strip. 12 or 24Vdc is still needed to power the neon, it is just able to operate in much longer lengths without the usual voltage drop issues that plagues an equivalent constant voltage product. Some of our constant current models, when specified in 5 Watt per metre specification, can be run in a single length of up to 28 metres powered from a single end! This doubles to 56 metres if powered from both ends.

PVC or Silicone Housing?

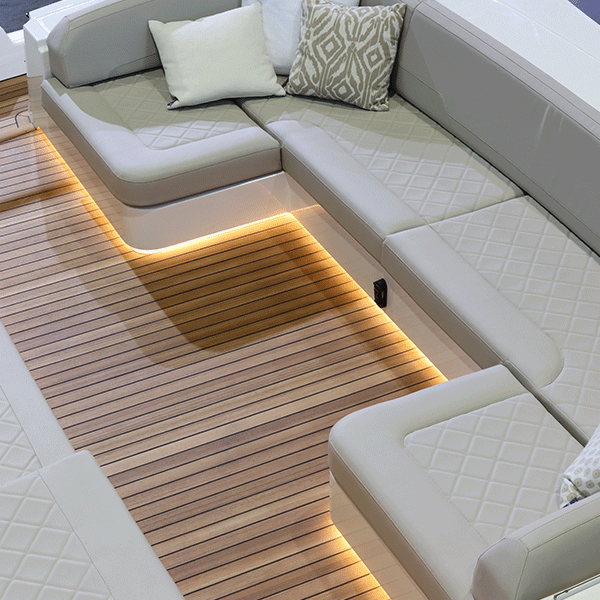

The environment application of the neon will also influence the product chosen. For exterior use in a harsh environment then PVC is the right choice. This includes outdoor installations on yachts, buildings or in indoor environments such as spas; even underwater in swimming pools where the PVC housing is chlorine and bromine resistant.

For applications where the CRI (Colour Rendering Index) must be greater than 90 and the Lumen output must also be high, then the silicone housed neon’s provide a better solution. In a silicone housing, we have a larger range of power outputs in both Top View, Side View and 3D Bend models. The lens on a silicone product is also a more aesthetically pleasing ‘milk white’ when off which offers a much more appealing product for installations where the lens is in view. Silicone neon is however only IP67 rated and cannot be used in underwater conditions.

Silicone Top View Neon Flex installed in a downward facing orientation

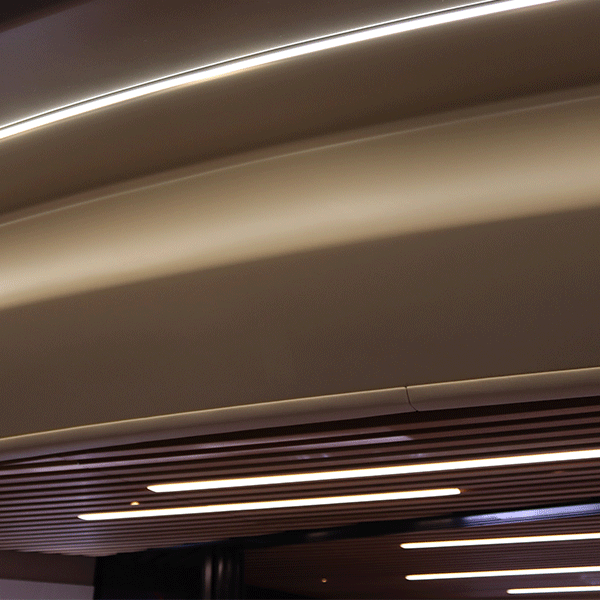

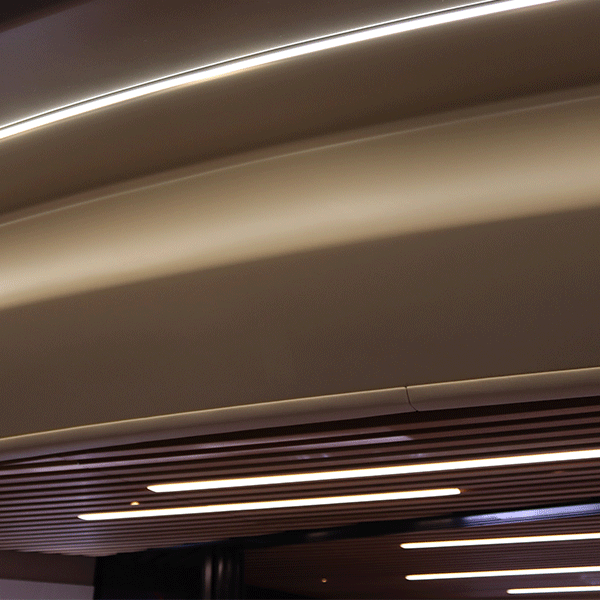

Silicone Side View Neon Flex installed next to a ceiling panel in a downward facing orientation

PVC Top View Neon Flex close-up

PVC Side View Neon Flex installed externally on a yacht in a upward facing orientation

Injection Moulded Connectors or DIY?

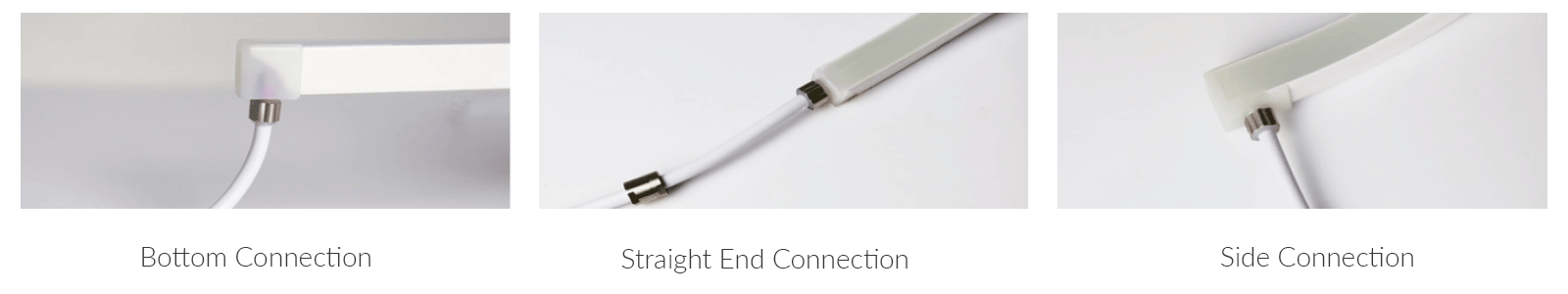

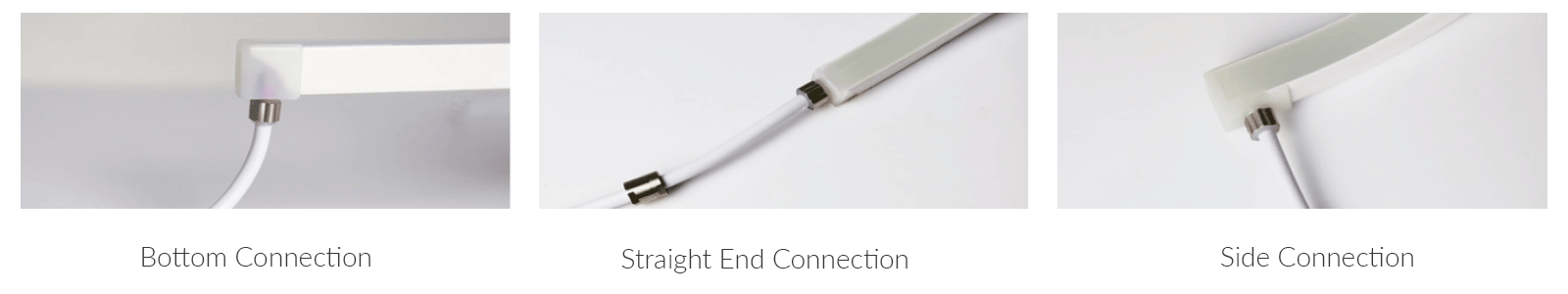

Here at Timage we offer a made to measure service for our LED neon products. That is, a client can specify several lengths required for a project and we will prepare these and deliver in a single kit. With this approach, we can offer our injection moulding service for the end connectors which ensures the IP rating of the product is not affected in any way and the connector remains a neat in-line solution. This service is essential for harsh environment or wet area applications where product resistance and durability are key. Ensure that you take note of the cut points of each product as we can only produce the neon strips to lengths divisible by this, unfortunately the LED strip we use cannot be cut just anywhere. Another specification point to consider when designing your LED neon kit is the direction of cable exit from the product. With most of our neon products, we can offer a standard straight end connector, a bottom connection, or a side connection. We can even offer a custom input cable length.

If you prefer a solution that can be cut and terminated on site, then our DIY option is best. The downside of the DIY method is that the connectors and end caps are bulkier than the LED neon profile so an allowance must be made for this in its installation.

We have recently released a Neon Flex LED Strip Lighting Overview on YouTube, view the complete video below.