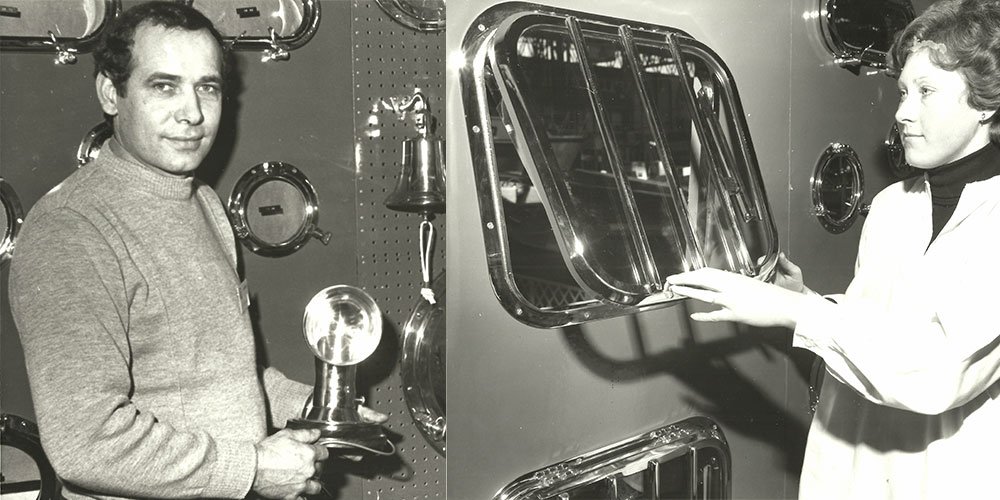

Meet the Team - Marcus and Oliver Lanza

(Above - Oliver (L) and Marcus (R) Lanza, in the warehouse)

Timage is proudly a family-owned business, still to this day. The two sons of the company founder, Giorgio Lanza, are both directors of the company. Marcus joined in 1988 and in 2012 was joined by his brother Oliver. In this blog I spoke to them both about how the company was founded and their plans for the future.

Timage was founded by your Father, Giorgio, tell me a little about how he started out?

O: The company was founded by our father in 1976 but did not really start trading in the marine products that we sell today until 1978. It initially consisted of the Foresti & Suardi products, so a lot of the deck hardware, bells, portholes, and hatches that we still sell today. Shortly afterwards, Besenzoni was added to his range with their aluminium table supports and swim ladders. Dad and Giovanni Besenzoni were school friends and grew up together in Italy and the Foresti and Suardi families were close friends. When Dad decided he wanted to work for himself in the mid-seventies and start a company he considered a lot of options regarding what he could sell. He looked at coffee machines, but England wasn’t ready for espresso machines back then – it could have been good, we might now be a Costa equivalent, who knows? But he settled on marine equipment because of his contacts back in Italy and also because there were a lot of prestigious boat builders in the UK at the time, a potentially great market. So, he set about trying to sell them the Italian wares that featured on the Rivas and other boats, Italian lake launches and bigger craft as well. But I do not think it was easy, people were wary about Italian products at the time.

M: Italy were in fact nautical market leaders at the time, now it is a level playing field, but back then the Italians were not afraid to push the boundaries and set the standard to which the UK producers could only dream of. Back then, the UK manufacturers were very conscious of what they wanted to spend on their products and made in Italy was perceived to be expensive

O: Dad always said that it was difficult back then to sell an Italian product because people believed that it was beautiful, but that it would last 5 minutes!

M: It was because of the cars; at the time you had the Fiats and the Lancia’s coming in and rusting all over.

O: That is why the company is now called Timage, we were called ‘Lanza Fittings’, but with an Italian name ‘Lanza’, our surname, it made it more difficult to sell our products. People thought ‘ah, its Italian, it won’t last five minutes’. Dad set about changing this view, and now everyone has a very different opinion.

How did each of you join Timage, was it always decided that you would join the family company?

M: I always knew I wanted to work here from the word go, I never had any dreams of going anywhere else because I love the marine industry so much. My dad said before joining the company he wanted me to know and work for the suppliers and get a better understanding of how they operate. I spent just over a year working in Italy, mostly at Besenzoni and a bit at Foresti & Suardi, on the shop floor. I had spent a lot of time here (at Timage) on my holidays and at boat shows – that is how I came in.

O: When I was a young boy I used to work at the shows, selling bells was my forte. We used to have a display with lots in a line and as a 10-year-old I would ring them all in an attempt to sell them which was good fun. I knew I always wanted to end up in the business eventually but for a few years I thought I was going to do something else – my mum was very persuasive to make sure I tried to do that! After my degree I did some work experience in London and worked for an insurance company and a few other bits, but I think Dad’s retirement – it got pulled forward a little bit – meant that there was an opening at Timage and it became obvious that I would come into the business, I did, and never looked back.

Oliver, Marcus has spoken about his time in Italy, did you also work there too?

O: Yes, I did for a year. I spent a year at Foresti & Suardi and a few months at Besenzoni helping to assemble passerelles. It was good for my Italian and product knowledge.

(Above: images from the factories of our products in manufacture)

What makes you proud of the company, has there been a particular accomplishment that stands out?

M: The thing that makes me most proud is when I see one of our products on a boat. The size and scale of the product does not really matter. But when I see the likes of a cabin door we have produced, fitted to a boat, and we have gone through the whole process of quoting, having an input into the design and then to actually see it fitted – that’s what gives me the greatest amount of pleasure, seeing the product being created, manufactured and then fitted. One of the projects I enjoyed the most was the clamshell balcony doors; it was an incredibly long process but when I got to the end, and saw each one installed, it provided me with a lot of satisfaction.

O: I think for me there are a combination of things. Although it was painful, I have been very pleased with the creation of the website, the new site linking to our ERP system which is also new. Rolling out a new computer system in a business is always a very difficult thing to do but I think now we are out the other side everybody is happier, I am proud that we managed to pull it off and our website is slick and efficient. Like Marcus said, I also like taking a product and going ‘right, let’s get this in with one of our customers because we believe in it and that’s the thing that makes you so proud of the achievement because you really truly believe in the product. With our Italian suppliers, we know all the people behind it, so you don’t just sell a light fitting, you sell that light fitting made by those people. I am quite proud that we have managed to re-establish ourselves as a top lighting supplier in the marine industry, having had some time away from the forefront. I think when people wanted cheaper and cheaper products following the financial crisis, we struggled to give them that, but now quality has come back, and we are here to fill that gap. We never gave in to the temptation to do things cheaply. So, I am really proud when you take a group of products that you believe in and then you go on the boat, like Marcus says, and you see them and the final effect. It is great to be so involved.

What goals do you have for Timage?

O: I want to continue to grow the architecture business, I want Timage to become more of a name than it is already. It is starting, but like anything it takes a lot of effort and energy. I would like Timage to not only be an FF&E (furniture, fixtures, and equipment) supplier to the marine but also to grow as a reputable supplier of FF&E to the architectural industry and the hospitality sector.

M: It is always about supplying quality bespoke fittings and being able to be proud and stand up for each of those. We don’t want to be a box mover and pushing thousands of items out of our stores. The goal is to keep the personal touch and the quality whilst scaling it up.

O: I also would like to see more embracing of technology; we have only just started with the website and the new system. We want to use the technology to make buying from us and using Timage as a supplier the most efficient, streamlined thing to do and that means we can put all our time into the personal side of things, so that the data and administration is something that just happens and that no one needs to deal with really. We both have a goal to continue to expand, and we hopefully will move next year to a brand-new premises. An 8000sqft facility in an eco-friendly industrial park with all of the right messages for the future. I think that, if anything, this move will cement the whole thing and bring us closer to achieving our goals. We are not just here to do a job, we are continually looking to innovate and better our business.

What do you feel is the biggest strength of the company?

M: That is easy, the people that work here, the team. A company is not a company without a team, there are no individual players, we are all together and it is all one central effort.

O: Yes, I would say everyone always puts in the effort, and we all want to do a good job. All of our staff are very knowledgeable and look out for the customer. I think that we have created, and kept hold of, a very good reputation for not only our product range but our aftersales. Timage is a family business to its core and I do believe that ethos rubs off a little bit on our customers who come and contact us and get that service and that result. We have staff that have been here for 25 years plus, so it is nice to have the familiarity and commitment to the company from them.

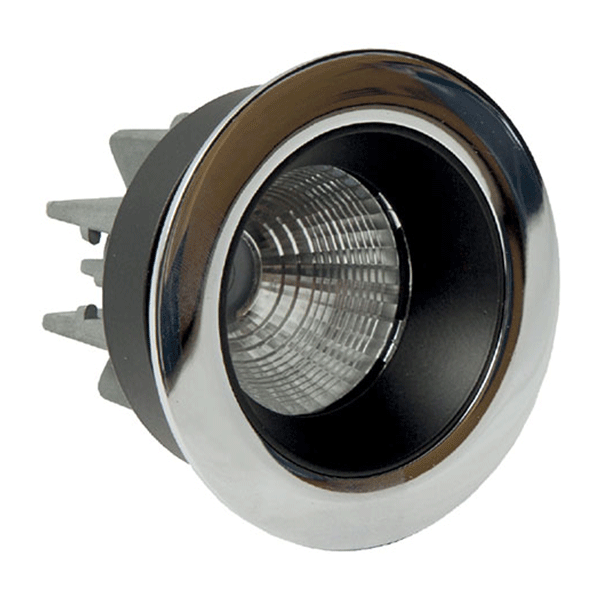

(Above: Oliver's favourites. Left - our 5289 Plutone Spotlight, Right - our 6138 Volans Spotlight)

(Above: Marcus' choice - our cabin doors. Photo courtsey of Sunseeker International Ltd)

Finally, the question I ask everyone, what is your favourite Timage product and why?

O: That’s a good question, because there are thousands and we both like them all.

M: Mine would be our cabin doors, you may not know that we do them, but it is something custom that we do for a very select number of clients and they are beautiful – the finish is superb.

O: I guess mine is lighting, lighting is something I am passionate about and really enjoy. I like our new range of downlights and spotlights; they really are some of the best on the market across all industries. Also, the neon flex strip LED we sell is great. The product makes such an impact in any space and it is a clean product, nicely designed, good value and high performing. Choosing my favourite product is a bit like picking your favourite child though! I only have a daughter so she is my favourite of course but I can imagine if I had five and someone asked me to choose which one was my favourite I wouldn’t be able to tell you. It feels a bit like that, a bit cheesy but it’s true. We are both truly passionate about our products.